Advanced Servo Motors ...

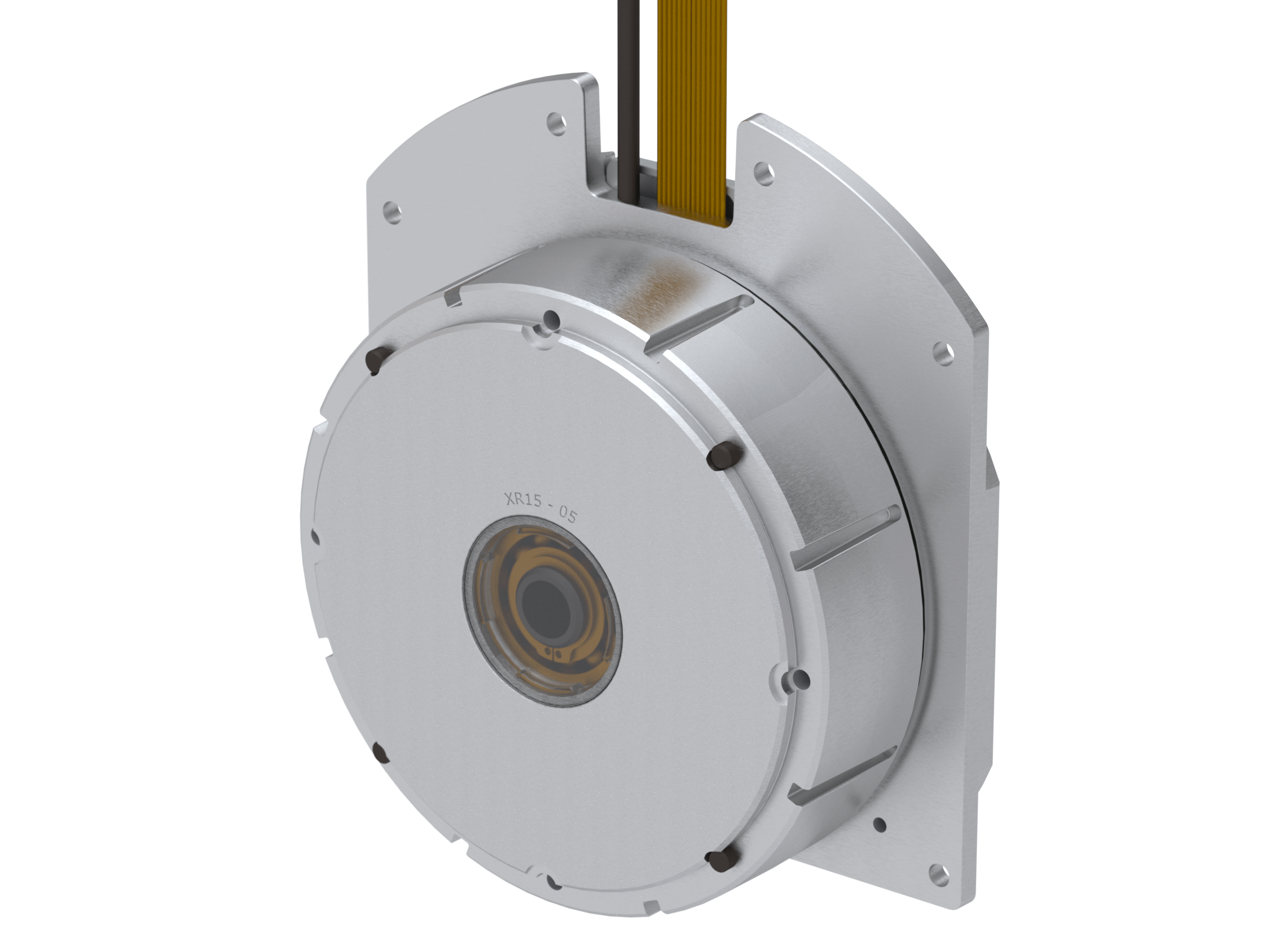

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

Industry

Defence ...

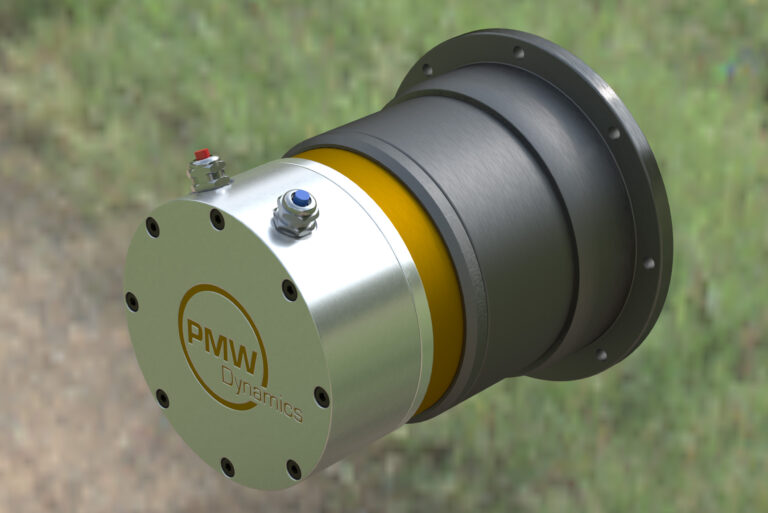

With its demand for equipment with extreme reliability and ruggedness, often for operation in confined spaces, the defence sector is a prime market for PMW’s compact motors

The company’s brushed printed armature DC motors are powering applications in military installations and vehicles, and are ideally suited for applications calling for low profile motors in environments where they may have to remain operational in temperatures of up to 150°C (302°F). These include motors for cooling fans, air movement fans, turret turning motors and positioning systems

Brushless motors from PMW are used in the manufacturing process of wheels and winches for bomb disposal robots, and for propulsion units for underwater use.

Get your custom designed motor

Get in touch